ÚLTIMAS NOTICIAS

NOTICIA PATROCINADA

RENOVABLES

Lo que necesito saber sobre…

- Tarifa regulada PVPC y Tarifa de mercado libre

- Qué potencia contrato, periodos de discriminación horaria

- Cómo mejorar la eficiencia energética en casa o en la empresa

- Consejos útiles para ahorrar

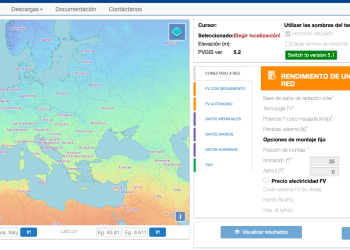

- Qué hacer para poner una instalación de autoconsumo fotovoltáico en casa

- Qué hacer para poner una instalación de autoconsumo eólico en casa

MÁS NOTICIAS

ENGIE construirá la planta de autoconsumo solar industrial más grande de Asturias

ENGIE y DuPont han cerrado un acuerdo para la instalación de una planta fotovoltaica con fines de autoconsumo en el...

MITECO lanza la concesión de acceso a la red a instalaciones de generación o almacenamiento síncronos en nudos de transición justa

MITECO ha publicado la Orden TED/345/2024. Regula el procedimiento y los requisitos aplicables para la concesión de acceso a la...

Jornada de Funseam y Exolum sobre el papel clave del hidrógeno renovable para la descarbonización y la movilidad sostenible

Funseam y Exolum han celebrado un seminario sobre el hidrógeno renovable como activo clave para la descarbonización de la sociedad...

Marina Serrano, presidenta de aelēc, alerta sobre los riesgos de la falta de desarrollo de las redes de distribución eléctrica

Marina Serrano, presidenta de aelēc, la Asociación de Empresas de Energía Eléctrica, ha hecho unas declaraciones sobre la falta de...

Hannover Messe pide señales claras para un nuevo comienzo en la industria

La fuerza innovadora de las empresas que participan en HANNOVER MESSE es mayor que nunca, y la mayor presencia de...

Proyecto Emuflex: todo un banco de pruebas para que las empresas testeen cualquier producto en la red eléctrica

La coordinación del proyecto Emuflex está a cargo del Instituto Tecnológico de la Energía (ITE). Participan cinco empresas del sector...

La Coalición del Hidrógeno Renovable europea pide a los nuevos legisladores, tras las elecciones, un plan de expansión inmediato

El Manifiesto de la Coalición del Hidrógeno Renovable europea ha pedido un plan de expansión inmediato tras las próximas elecciones...

Soltec lanza SFOneX, su sistema de doble fila más largo

Soltec ha anunciado el lanzamiento de su nuevo seguidor solar SFOneX. Con una longitud de 125 metros, es el sistema...

El Consejo de Ministros aprueba una modificación puntual al Plan de Desarrollo de la Red de Transporte de Energía Eléctrica 2026

El Consejo de Ministros ha aprobado una modificación puntual al Plan de Desarrollo de la Red de Transporte de Energía...

El papel clave de los biocombustibles en la transición energética

El CEO de Exolum, Jorge Lanza, ha participado en el foro Wake Up Spain!, en el que ha puesto de...